There are no future dates for this course

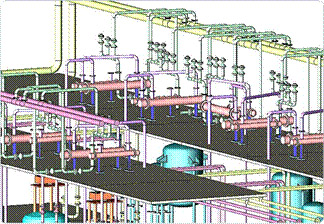

This 3 days course is designed to meet the needs of Engineers, Technicians and personnel of all disciplines (Quality, Safety and Process/Production) from Design, Construction and Owner Companies

Objective

Who Should Attend

Industrial and commercial plant and facilities engineers and operators, project engineers, design engineers, Quality and Safety personnel who are involved in the design, construction and operation of a process plant. Professionals who need to add to their current experience and knowledge of mechanical engineering. Mechanical engineers who require practical knowledge of certain aspects of mechanical engineering or who need to refresh their knowledge. New graduates will benefit from the practical industrial experience of the instructor.

After Attending This Course You Will Be Able To

Program Outline

Day 1

Materials

Piping

Day 2

Welding and Inspection

Flexibility Analysis

Pressure Testing

Day 3

Pressure Vessels

Heat Exchangers

Pumps

Compressors and Fans

Mechanical Seals

Piping Drawings

Codes, Regulations, Standards

TLNT reserves the right to cancel or change the date or location of its events. TLNT's responsibility will, under no circumstances, exceed the amount of the fee collected. TLNT is not responsible for the purchase of non-refundable travel arrangements or accommodations or the cancellation/change fees associated with cancelling them. Please call to confirm that the course is running before confirming travel arrangements and accommodations. Please click here for complete policies.

We could offer any of our courses at a location of your choice and customized contents according to your needs, please contact us at : inhouse@tlnt-training.com or click here to submit an online request.

Each participant will receive a complete set of course notes and handouts that will serve as informative references.

Interested in this course?

Click Here

Jumpstart your training with the help of Talented Technology Training Canada (TTT-Canada) & the Canada Job Grant.

Seminars and Workshops offered within your organization anywhere in the world.

To Register by fax, download and fill our registration form, then fax it to (888) 849-4871. Mail your cheque to our address.

If you have a question regarding this course, please click here to contact us.A certificate of completed Continuing Education Units (CEUs) will be granted at the end of this course. A fee is required for all complimentary webinars.

This course can be customized and delivered on-site at your facility.

Stay on top of your professional development with useful articles and industry updates Subscribe